Rebar is actually a basic metal bar or block that may be broadly employed in reinforced concrete and reinforced masonry structures. These rebars are frequently manufactured out of carbon metal which empower it to be recounted as reinforcing metal Or maybe reinforcement. Below Structural BIM Services Rebar detailing is really a discipline of making fabrication or store drawings of metal reinforcement with the development process. The internet site fabrication drawings which happen to be produced dependant upon style and design drawings for reinforcing steel are Rebar Thorough drawings. Engineers and Architects make design drawings to develop the necessary strengths determined by the rebar detailing that gives diameter, bar shapes, quantities, length of bars to facilitate your internet site for preventing delays and wastage thereby rushing The complete design process.

Every single rebar is in-depth symbolizing a condition, length, and diameter determined by the necessities with the style and design drawing. The Rebar placement will then be demonstrated at size which implies the concrete cover, precise area, and Particular method of placement if desired. The rebar details and bar bending schedules will show bar diameter, bar notation, the volume of bars, weight through the bars, and length of Each and every bar and also mentioning the whole fat towards the whole list of bars put throughout the drawing. During the preparing of rebar aspects, the stock lengths of bars are trapped in view in order that There is no wastage in the materials.

Rebar Detailing and Reinforcement concrete detailing might be modeled and coded in three-dimension Along with the 3D Modelling technological know-how like BIM Modelling Companies. The specialized rebar detailing software like Rebar CAD and AutoCAD employed for this reason may help every single member in the structural engineering to get ready layouts, doc, track, although overall Management.

Owning recognized theory notion of rebar detailing a location of structural BIM modeling, let us try and look at the importance about it in the whole development method is. Some in the factors are:

Importance of Rebar detailing in Structural BIM Modeling

When 2D drawings and bending schedules are usually produced and presented, the 3D design is usually issued to any or all the c's associates commencing the consulting engineer and contractor departments all the way down to the metal fixers which happen to be in the walk-out on-website. The combination on the two become Specifically a good selection for website personnel in which web page constraints or congestion of reinforcements continue being unidentified until you will discover reinforcement and fixation on-website page. For every single bar, the precise position of fixing is demonstrated inside the 3D product Besides any hindrances or obstructions.

Creating detailing reinforcements in 3D in the 2D procedure is not just speedier but modeling rebar in a three-dimensional surroundings will help remove clashes. Though modeling one can maybe visualize if any of the bars Never correct using a decided space, thereby detect all these kinds of clashes throughout the rebar drawings. There exists even the facility to examine the reinforcement in full element becoming a precise element illustration right before it is being ordered in the fabricator and complicated cages are assembled off-website.

When You will find there's suitable rebar detailing Remedy available, a successful and accurate reinforcement design website may be designed by importing structural calculations from the structural Examination system. With Automation included modifications can be reflected inside the 3D rebar detailing together with essential updates to drawings and schedules quickly when variations are produced elsewhere compared with possessing to execute handbook modifications to 2D sections and sights.

As opposed to determined by manual input from paper schedules, the rebar fabricator can extract knowledge specifically with the model to the equipment. The concrete pours may very well be properly-defined in the product with other particulars like quantities and volumes To make certain a lot more precision in handling materials deliveries. This will permit better Manage and carry about considerably less wastage and reduction of General charges.

Getting 3D detailed digital types will likely not restrict the gain using a single-stage like that in the engineering and detailing section but may very well be made use of during the phases. Acquiring reinforcement completely modeled in 3D, the contractor is confident that it will suit into areas if the time comes it to become fastened on-website. The information from the design could be utilized Within the subject to permit contractors to carry out a design-dependent structure from the usage of robotic total station equipment together with tracking rebar and components and identifying when and in which they will be required.

Fixers present on-site might be within the model atmosphere for the rebar detailing to correctly comprehend its application, i.e. exactly what is demanded where and when in contrast to counting on their interpretation of standard 2D drawings.

The structural engineers can simply just and more promptly deliver design reports, schedules, and drawings from a 3D model in comparison with second types, thereby boosting design efficiency. There is additional accuracy in cost projection determined by the rebar portions created from the 3D product as is usually more reputable as compared to second drawing take-offs. Not only this the quantities are wholly traceable, allowing comparisons and checks to receive conducted simply.

With these explanations, we can easily conclude that Rebar Detailing a self-control of Structural BIM Modelling Products and services is really a in the essential requirements for that Over-all success Along with the project life cycle. To summarize, possessing Rebar Detailing the rebar contractor can consider producing rebars there will likely be no need to estimate reinforcement specifications for procurements at the positioning as a result of productive 3D styles. The product will depict the requirement of anchors and laps inside drawings thereby making sure style and design adequacy together with decreasing wastage. The general squander and time delays are lessened at the web site since the many form drawings are usually out there. According to these records the bars might be quickly fabricated according to the styles and number of bars expected.

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Kel Mitchell Then & Now!

Kel Mitchell Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Susan Dey Then & Now!

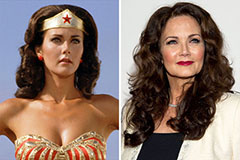

Susan Dey Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now!